Even a good welder also need things...

Welding Helmet

Welding helmets are headgear used when performing certain types of welding to protect the eyes, face and neck from flash burn, ultraviolet light, sparks and heat. Most commonly used with arc welding processes such as shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding. Welding helmets are necessary to prevent arc eye, a painful condition where the cornea is inflamed. Welding helmets can also prevent retina burns, which can lead to a loss of vision. Both conditions are caused by unprotected exposure to the highly-concentrated UV rays emitted by the welding arc (which can also damage uncovered skin, similar to a sunburn. |

Welding Gloves

The importance of welding gauntlets is behind the safety they offer a welder. This is because they protect a welder's hands and wrists from heat and sparks while still offering the flexibility in performance to carry out professional welding without restriction. |

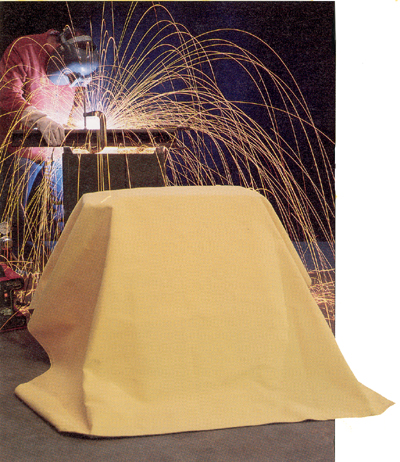

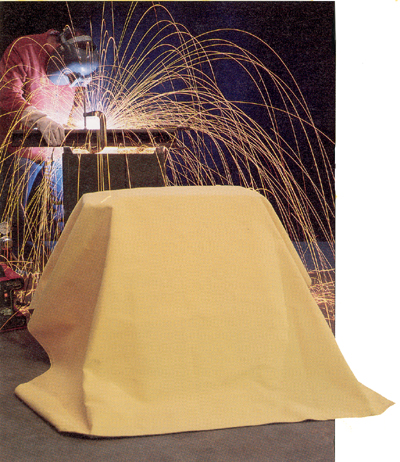

Welding Blankets

A welders blanket is uses as a form of safety protection for themselves and for those around them to stop sparks causing fires as burning embers land around them. |

Welding Curtains

For safety reasons curtains for welding have been created to reduce hazards such as fires by isolating the area a welder is working in. Welding curtains have been specifically designed to reduce the risk of passing workers being injured by sparks and stopping burning embers before they can find a material that is flammable. |

Welding Jacket

A welding jacket is a necessity for most welderes. For any welder safety is paramount and never far from their thoughts. This happens because of the heat and potential dangers associated with welding. |

Welding Screens

A welders screen is rectangular metal frames with a heat resistant welding screen in the middle of the rectangular frame. The heat resistant screen is usually joined to the metal frame through a metal hook that goes through holes at the top of the metal frame and brass eyelets on the heat resistant screen. At the bottom of the metal frame, at each end, there is a T-section metal frame with two wheels on casters; this gives the welding screen stability and maneuverability. |

Welding Tools

Welding tools and metalworking tools is like a kitchen without utensils |

by:kirk kervin orpilla

0 comments:

Post a Comment